Sarfaraz K. Niazi Ph.D.

can you accelerate aging? ask a Scientist

Sarfaraz K. Niazi Ph.D. is the largest solo inventor of bioprocessing inventions with over 100 inventions (31), additionally including new drugs, new dosage forms, bioequivalence testing methods and a large number of other patient-related inventions that are widely used across the globe. His patented invention of demonstrating analytical similarity methods (32) was accepted by the FDA to allow waiver of patient trials of biosimilar products.

Simple yet complicated process

Our beverages are designed to enhance the palate, providing a remarkable experience, all based on the modern sciences of thermodynamics. Just as pure as a long-aged beverage, our products are unique and significantly more exciting.

INTRODUCE BIOPROCESSING techniques TO THE production PROCESS

Increase diffusion flux by 1000x+

Proprietary method of wood pulverization

Natural handshake between beverage and wood

Temperature cycling to drive aromatic and non-aromatic fast

Multiple woods, no porosity limitation

Color, taste and smell titration

Consistent quality attributes—tested

Continuous process

Universal application

CFR Compliant for labeling

Background

Alcoholic beverages have fascinated humankind for millennia, starting with a serendipitous discovery of alcohol from the yeast fermentation. For a long time, we imbibed that awful smelling and tasting freshly fermented liquid because we liked what it did to us. With time, we needed a utensil to store our raw alcohol, and the only obvious choice was a wooden barrel; we may have tried many kinds of wood to make these barrels, but oak won because of its tight grain that reduced the loss due to evaporation, the angel’s cut. We found that keeping our alcoholic beverages in an oak barrel, it tasted and smelled better and the longer we kept it locked in, the more enjoyable it became. The observation that over time, the beverages improve, began the art of aging alcoholic beverages. Today almost universally, the aging of alcoholic beverages is in wood barrels, a norm to enhance their quality: a process that can last for decades. At Wiseman Beverages, LLC, we examined the science behind aging and what happens when we leave an alcoholic beverage in a wooden barrel? What we learned allowed us to deconstruct the myth of aging alcoholic beverages. The physics and chemistry of aging are not difficult to understand, but to replicate it in a short time is complicated. We developed patented technology and a myriad of proprietary techniques, equipment, methods and other details to enable us to design an alcoholic beverage to any standard of flavor and taste in a continuous manufacturing process.

Alcohol Distillation

Column Distilling came out of the success of pot distilling. By the 19th century, commercial distillers were looking for a faster distilling method as pot stills require cleaning after every batch. Robert Stein and Aeneas Coffey separately invented and improved upon the process of “column distilling,” which involves giant gleaming columns. Whatever the distillation process, alcohol never evaporates alone. Congeners (tannins, esters, fusel alcohols, and even methanol) can evaporate with it. Methanol that is removed as it evaporates at 148.5 F, so any liquid that shows up before 173 F (the boiling point of safe, delightful ethanol) is discarded.

Aging

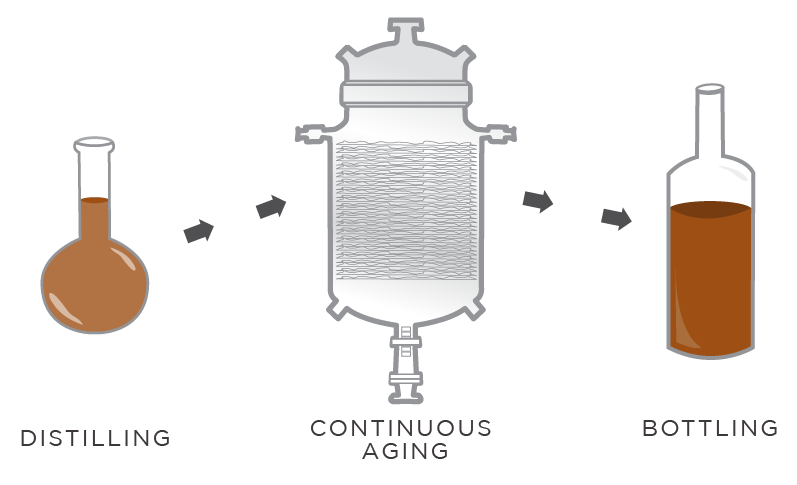

Now, this is where we come in.While gin and vodka are not aged, whiskeys are traditionally subject to a long and complex process of “aging,” essentially let the freshly distilled alcohol sit in a wood barrel, generally white oak is charred. The longer the barrel is stored, the higher is the price because of the assumed connection between aging and flavor and taste of the product. At Wiseman Beverages, LLC, this was our mission and to emulate the aged whiskey our objective, all at a cost that will make this so highly revered beverage to all. Whiskeys do not mature in the bottle, only in the cask, so the “age” of a whiskey is only the time between distillation and bottling.Our process allows us to save years on the process by reducing the aging segment to hours. Whiskeys held in bottles for many years may have a rarity value but are not “older” and not necessarily “better” than a more recent whiskey that matured in a barrel for a similar time. After a decade or two, additional aging in a barrel does not necessarily improve a whiskey.

Extraction: The Wood

It all begins with the wood that comes in contact with the distillate resulting in the extraction of chemicals from the complex structure of the wood. The chemical composition of wood varies from species to species. We can use traditional charred oak along with a verity of species to emulate traditional or create new flavor profiles.

Partitioning

An average barrel with a 53-gallon capacity provides a maximum contact surface of about 1.8 m2, in a full barrel. The extraction of the myriad chemical in the wood begins arriving in the alcohol almost instantly based on a well-defined principle: the Fick’s First Law of Diffusion. Briefly, the rate and extent of extraction is dependent on the solubility of the extractant in alcohol, the surface area of wood exposed to alcohol; the temperature affects solubility and also imparts kinetic energy to molecules coming out of wood, while reducing the thickness of the layer of concentrated liquid at the surface of the wood.

Evaporation

Though the oak is one of the tightest grain woods, its construction without using any glue and other imperfections allows very slow evaporation through the walls. While the angel’s share substantially adds to the cost, it also serves another purpose that is not widely appreciated. With all other factors being constant, the components that have a lower boiling point (higher vapor pressure) will evaporate first and faster—over time, this creates a unique gas chromatography, and the angel’s cut brings a significant change in the chemistry of whiskeys. All craft distillers work to minimize the angel’s share and miss out on a significant step in the improvement of the whiskeys.

Reaction

With thousands of different molecular structures floating in the barrel, there goes on extensive reactivity of chemicals, those coming from the wood reacting with other and with chemicals in the distillate. The chemicals in the wood are locked in and unable to react, but once present in a solution state, they are free to interact. The speed and extent of the reaction depend on the activation energy required for a reaction to take place, as described in the Second Law of Thermodynamics. A common knowledge it is that the taste of whiskeys aged in different environments is unique, mainly because of the atmospheric conditions including storage temperature. However, the reaction rate is extremely slow taking years to achieve a desirable concentration of desirable chemicals. Five factors affect the rate of a chemical reaction; concentration, temperature, surface area, nature of reactants, and catalysts.

Innovative Process

The patented technologies of Wiseman Beverages, LLC are based on each of the scientific principles described above--understanding these principles allows the selection of optimal techniques to accelerate the aging of our spirits. The guiding principles include:

· Replicate the process that is centuries old—no additives, no changes in reaction stages.

· Continuous process, a first of its kind in the industry—no holding tanks, no batch processing.

· Linear acceleration of reactions—same results as in the slow process

· A million times faster extraction, with temperature cycling

· Continuous preparative column chromatographic

· Angle’s share forced

FASTER AGING OF ALCOHOLIC BEVERAGES

Humans have the ability to taste millions of tastes and over a trillion smells, there is no limit to tantalizing experience in tasting alcoholic beverages. Our technology breaks the classic aging barriers that are archaic and redundant, as we are able to reach the same organoleptic experience almost instantly, without modifying the natural mechanism of aging.

ACCELERATED AGING OF WINE AND SPIRITS

While many attempts have been made in the past to accelerate the aging of alcoholic beverages, there remains an unmet need to invent a process or a system that would allow aging to proceed extremely fast without modifying the natural process of aging that imparts a unique character to alcoholic beverages.

FASTER AGING AT A CONTINUOUS FLOW

“Whether it is whiskey, tequila, or wines our patented technology allows us to emulate the flavor of any targeted beverage.”